AN INDUSTRIAL SHREDDERS SOLID PROJECT DEVELOPMENT AND PRODUCTION REFERENCE POINT

A team of dedicated technicians is always available to provide the most suitable solutions to the customer needs.

Thanks to the in-depth knowledge of steels and the treatment of waste different types related applications, we can always guarantee the best solution.

We manufacture our shredders completely within our departments, carefully selecting the materials and adopting the most advanced production techniques.

We scrupulously check all the manufacturing phases of each single component, tracing the detailed history of each of them to be able to reproduce it faithfully at any time.

This is our machines added value.

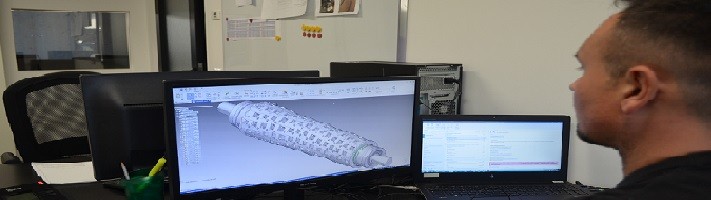

DESIGN

The research and development department is made up of technicians with great experience in the design of machines for the industrial waste volumetric reduction and recycling.

The new patented solutions make WRS shredders unique in terms of productivity and configurability.

BEST STEELS SELECTION

The choice of the best steels for each type of machine part is made by qualified technicians with many years of experience in this sector.

PROCESS

The components are processed internally, ensuring quality and compliance with the agreed delivery times.

THERMAL TREATMENTS

The shredder grinding group consists of blades made of a material suitable for the shredding needs, selected on the basis of the necessary chemical and physical features.

Each group is heat-treated to get a hardness grade which allows to perform in the best possible way, according to the right compromise between wearing time and resistance to the mechanical stress.

ASSEMBLING

The mechanical parts coming from the dimensional control department arrive in specific pre-assembly areas. After the “squaring” of the grinding box we prepare the elements of the gearbox, assembling the gears, the shaft seals and finally the shafts. After joining the latter with the gearbox upper half, we proceed with the assembly of the grinding unit.

RUNNING SIMULATION

In our premises we set up an area to test complex systems, equipping it with tools and accessories that allow us to simulate the operation of our machines. The tests can also be carried out using waste samples supplied by the customer, excluded samples belonging to dangerous categories.

The equipment consists of:

- over-belt magnetic separator

- eddy currents separator

- magnetic pulley

- rotating screen with different grids

- vibrating table

- conveyor belt

- densimetric separation system